Funfair Rides From Drawing Board To Finished Article

Someone asked me recently who builds funfair rides. Well, there are a number of long established companies going back in some cases a considerable number of years. Like much of industry, the major manufacturers are European. There were a number of UK based builders making large adult rides, but these are by and large defunct.

The smaller children’s rides market is much healthier. A number of excellent rides are turned out for the home market and occasionally for export. Many of the started as travelling showmen, who perhaps built a ride for themselves, and were then asked to build another for someone else. Most end up building an occasional ride as a sideline, but some turn it into their full time occupation.

Fairtech Fabrications Ltd

One such company is in the hands of a friend of mine, his wife is my wife’s first cousin so there is once again a family connection. Along with his two sons, he has always worked on his own equipment to a high standard, and when recently the number of fairs he attended was cut drastically he looked at leveraging his building prowess into a full time gig.

This post is going to follow the design and build of one of his rides.

Cups And Saucers

The cups and saucers, or teacups as they are sometimes known, isn’t a new ride. Its been one of the staples of the funfair industry over here since I was a teenager, some 35 years or so. So was a good bet for a saleable product.

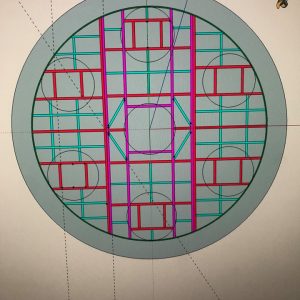

Like most things now, the ride started on a computer. Initial drawings were made to produce the layout of the steel work and electrics/hydraulics. Once these were satisfactory, more detailed drawings with correct dimensions and material tolerances were produced, enabling construction to begin.

Initial Steel Work

The bulk of the funfair ride construction is box section mild steel. This is fabricated into a number of section for the ride bearing chassis, the moving part of the ride, and the support items such as the light posts and speaker brackets. Parts such as hydraulic valves and rams, electric motors etc are attached to the basic frame.

The basic frame is built up and disassembled a number of times. Things like the decorative centerpiece need to be attached to ensure the mounting holes and suchlike are in the correct places. The aluminium tread plate needs cutting to size and fitting to ensure it all matches. Slew rings to allow the cups to spin have to be in position to ensure they are level and running free and to tolerance.

Hot Dip Galvanising

The ride is pretty much built to a finished standard, except for the decorative sections. It is then stripped down completely and sent to have the full metalwork hot dip galvanised. This is a method of submerging the steel in a molten zinc bath, to apply a protective coating. This can extend the life of the rides structural components to in excess of 50 years. Untreated steel without regular maintenance can start to degrade in less than 5 years. In a marine environment it can be as little as 1 year before rust starts to attack the structure.

Assembling The Finished Ride

Once the galvanising is complete the funfair ride is assembled again. Sometimes it is possible for the heat of the galvanizing process to warp the steel sections, so any that are out of specification. may need to be rebuilt or replaced.

Once the structure is to the builders satisfaction, final assembly can begin. The chassis is assembled, and then the circular frames carrying the cars built up and attached to the chassis. At this point the electric cabling, braking systems and hydraulic systems will be attached.

Over the last few years the Health and Safety Executive have started tightening up on the use of barriers around children’s rides, to meet both this requirement, and with an eye on the European market, Fairtech made the decision to go for the more stringent TUV approval, which is regarded as a must have in many export destinations. This involved additions to the rides such as a barrier to prevent a child being able to walk up and touch a moving part of the ride.

Additionally on the older designs, the cups were not locked in place, smaller children exiting the cup could slip and fall as the cup spun. Fairtech have added an automatic locking system, so once the rides stops, the cups lock in place. They also added some nice touches to the the chequer plate flooring. The ride is finished off with LED lighting to help meet current environmental regulations, and a Bose music system.

Final Funfair Ride Assembled

The final ride with full decoration, music, lighting and automatic gates to allow the riders to access and exit the ride.